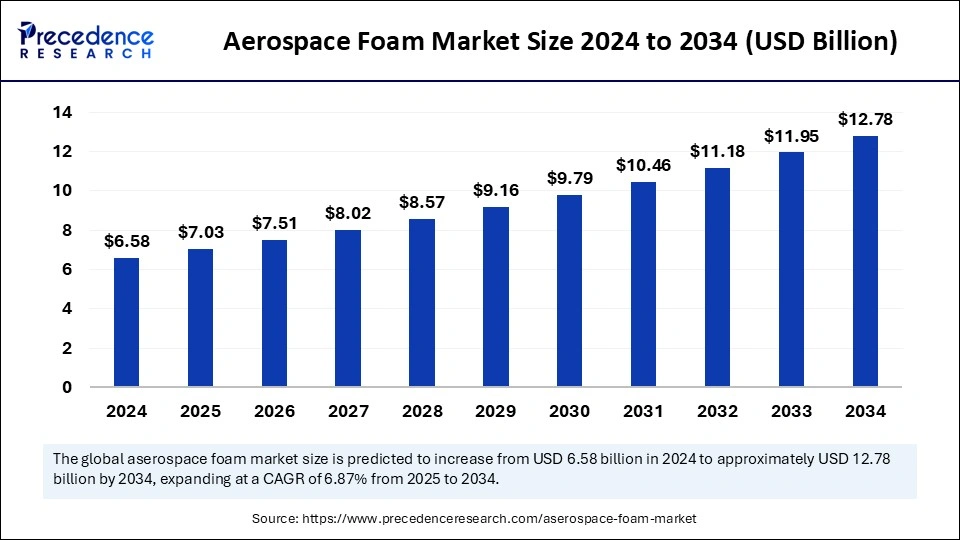

Aerospace foam market size to expand from USD 6.58 billion in 2024 to USD 12.78 billion by 2034, growing at a steady CAGR of 6.87%.

Aerospace Foam Market Key Takeaways

-

In 2024, North America captured the largest market share at 36%.

-

Asia Pacific is set to grow at the fastest rate in the coming years.

-

Among foam types, polyurethane foam led the market in 2024.

-

The EPE foam segment is predicted to experience significant expansion over the forecast period.

-

The carbon walls and ceilings segment held the highest market share in 2024 by application.

-

Aircraft seats are expected to register notable growth in the application segment throughout the forecast span.

-

Commercial aviation was the top end-use segment in 2024.

-

Military aircraft are forecasted to grow at a solid CAGR over the predicted period.

Aerospace Foam Market Overview

The Aerospace Foam Market is undergoing a transformation driven by advancements in material science and a shift toward sustainability. Aerospace foams are essential in modern aircraft for applications including thermal insulation, impact resistance, and structural reinforcement. With airlines and aircraft manufacturers focusing on reducing carbon emissions and improving fuel efficiency, the demand for lightweight aerospace foams has surged. The market is also benefiting from increased global air travel, the expansion of low-cost carriers, and heightened defense spending on next-generation military aircraft.

Aerospace Foam Market Drivers

One of the primary drivers of the Aerospace Foam Market is the growing emphasis on weight reduction in aircraft manufacturing. Aerospace foams provide excellent strength-to-weight ratios, making them ideal for improving fuel efficiency and enhancing aircraft performance. The demand for enhanced passenger comfort and safety has further boosted the use of high-quality foams in seating and cabin insulation. The defense sector remains a major consumer, as military aircraft require robust materials that offer impact resistance and thermal protection in extreme conditions. Additionally, the increasing use of composites and hybrid materials in aircraft construction has led to innovations in aerospace foam formulations, enhancing their durability and functionality.

Aerospace Foam Market Opportunities

Significant opportunities lie in the development of sustainable aerospace foams made from bio-based and recycled materials. Research into advanced nanostructured foams is also opening new possibilities for lightweight and high-strength applications in both commercial and defense aviation. The expansion of the space industry, including satellite launches and space tourism, presents another growth avenue, as spacecraft require specialized foams for insulation and vibration damping. The rise of autonomous air mobility, including air taxis and electric vertical takeoff and landing (eVTOL) aircraft, is expected to create new demand for innovative aerospace foams that combine flexibility, strength, and thermal resistance.

Aerospace Foam Market Challenges

Challenges in the Aerospace Foam Market include stringent environmental regulations that require manufacturers to develop low-emission and non-toxic materials. The volatility of raw material prices, particularly for high-performance polyurethane and polyimide foams, poses cost-related challenges for manufacturers. Ensuring consistent quality and meeting rigorous aviation safety standards also add complexity to production processes. Moreover, competition from alternative lightweight materials such as carbon fiber composites presents a challenge, requiring foam manufacturers to continuously innovate and improve product performance.

Aerospace Foam Market Regional Insights

The United States and Europe remain the largest markets for aerospace foam, driven by their strong aviation and defense industries. Asia-Pacific is witnessing rapid growth, with China and India expanding their commercial and military aircraft fleets. The Middle East is emerging as a key market due to increasing airline investments and airport infrastructure development. Latin America and Africa are seeing gradual growth, driven by regional airline expansion and government investments in aviation.

Aerospace Foam Market Recent Developments

Recent innovations in the Aerospace Foam Market include the development of ultra-lightweight foams with improved thermal and acoustic insulation properties. Leading manufacturers are focusing on eco-friendly foam alternatives to meet global sustainability goals. Strategic partnerships between aerospace and material science companies have resulted in breakthrough technologies that enhance foam durability, fire resistance, and mechanical performance. The rise of 3D printing technology in aerospace foam manufacturing is also gaining traction, allowing for customized and complex foam structures tailored to specific aircraft needs.

Aerospace Foam Market Companies

- Boyd Corp.

- Evonik Industries AG

- ERG Aerospace Corp.

- SABIC

- BASF SE

- ZOTEFOAMS PLC

- General Plastics Manufacturing Company

- Solvay

- UFP Technologies, Inc.

- Recticel NV/SA

- NCFI Polyurethanes

- DuPont

- Rogers Corp.

- ARMACELL

Segments Covered in the Report

By Type

- Polyurethane foam

- Polyethylene foam

- Melamine foam

- Metal foam

- Polyimide foam

- Polyethylene terephthalate foam

- Polyvinyl chloride foam

- Specialty high-performance foam

By Application

- Flight deck pads

- Carbon walls and ceilings

- Aircraft seats

- Aircraft floor

- Others

By End-Use

- General aviation

- Commercial aviation

- Military aircraft

- Rotary aircraft

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

Ready for more? Dive into the full experience on our website!